- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

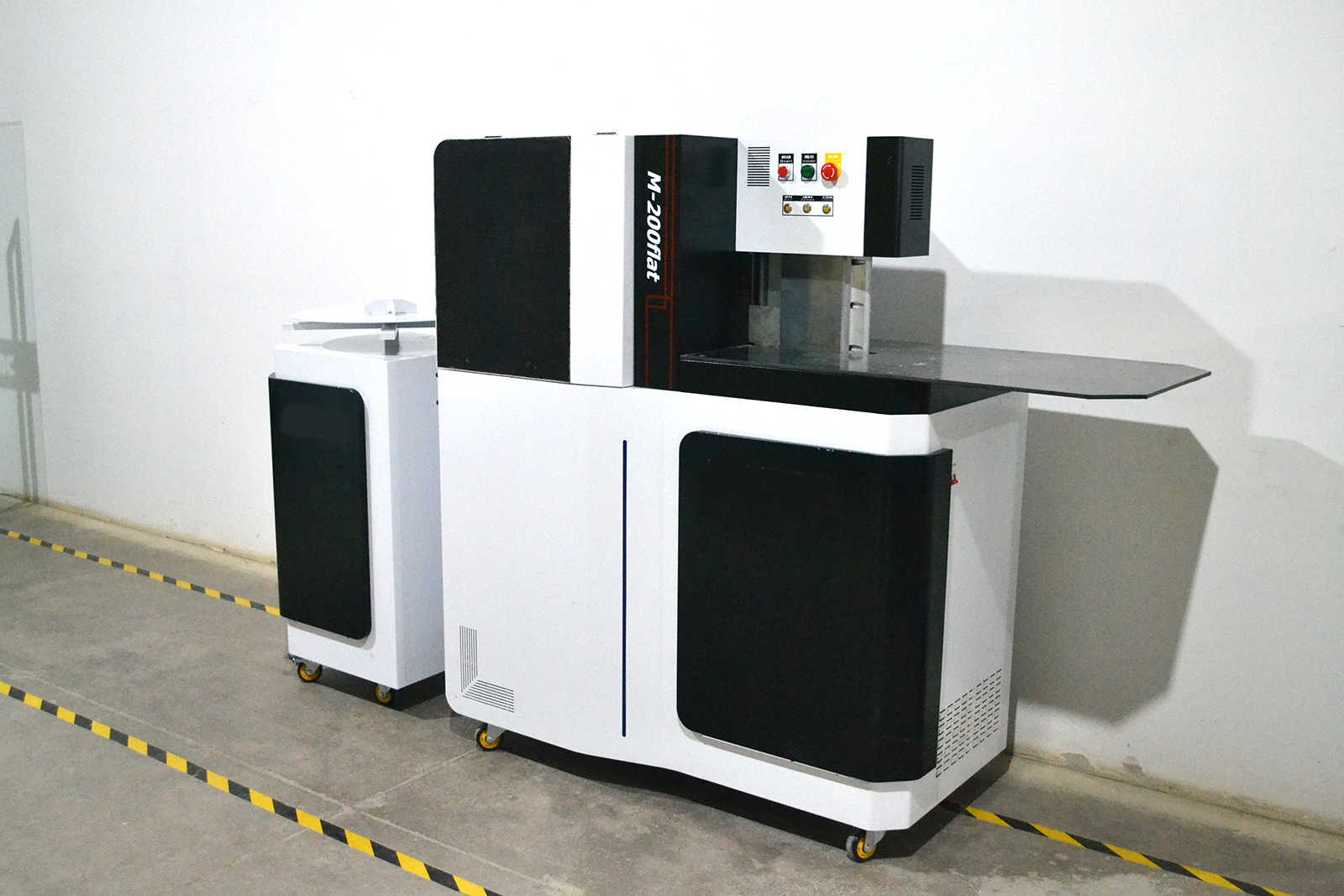

Product Introduction

Question 1-Product Description

Question 2-Product Parameter

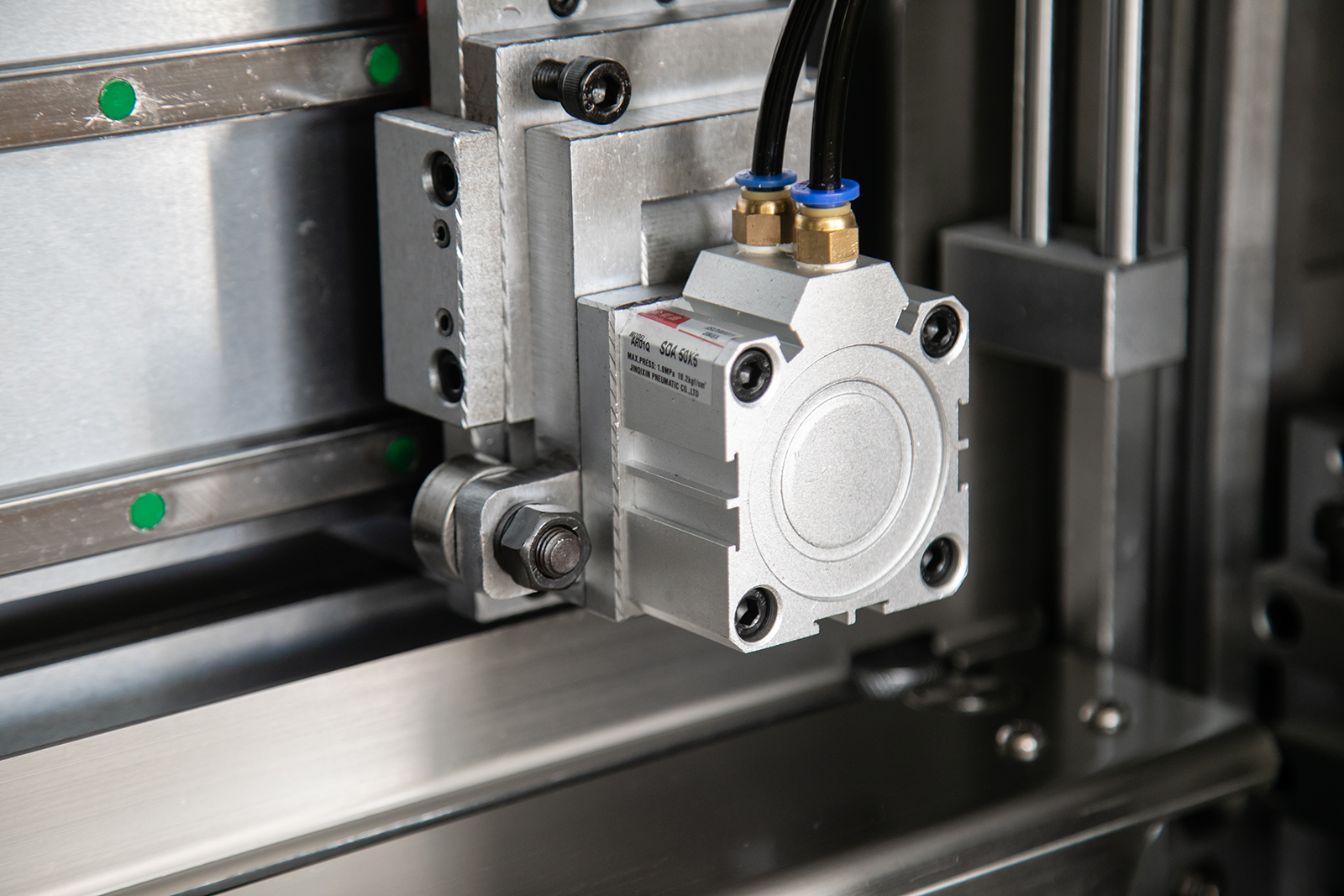

Hardware | Feeding system | Precision screw transmission and mechanical arm alternatively feeding structure (closed loop self-test system) |

Slotting system | Hard alloy planer | |

Bending system | Double -pole alternate part-arc institution and patented alternative arc-extrusion structure | |

Driving motor | Servo motor 3 set, stepper motor 1 set | |

Equipment weight | 480 KG | |

Dimensions | Body L2300*W700* H1570mm / Feeding table L500*W500*H1200mm | |

Performance | Material category | Flat aluminum /Stainless steel / Galvanized plate (height: 20-200mm) |

Material thickness | Flat aluminum :0.6 - 1.5 mm/ SS :0.3-1.2mm / Galvanized sheet:0.4-1.2mm | |

Support format | AI / PLT / DXF | |

Feeding accuracy | Length + 0.1mm Radius > 4mm | |

Software | Control card | Leetro Four -axis motion control card |

Software system | Auto drive / CBS4 auto bending system | |

Input voltage | 220V 50Hz 3KW | |

Air pressure | 0.6-0.8Mpa |

Question 3-Product Display

m200-6

m200-7

Question 4-Application

Question 5-FAQ

Question 6-Our service

Hot Tags: stainless steel bender

You Might Also Like

-

High-Efficiency Combustion System Helps Food Processors Achieve Energy Savings and Cost Reductions

-

Jordan gas burner with high pressure blower

-

Shipment of heavy oil burners to French customers

-

Gas Burner System Upgrade for Steel Heating Furnace in Pakistani Steel Plant

-

Spiral Plate Heat Exchanger for Vietnam Market

-

BNL10 Diesel Burner – Now Powering Industry in Angola